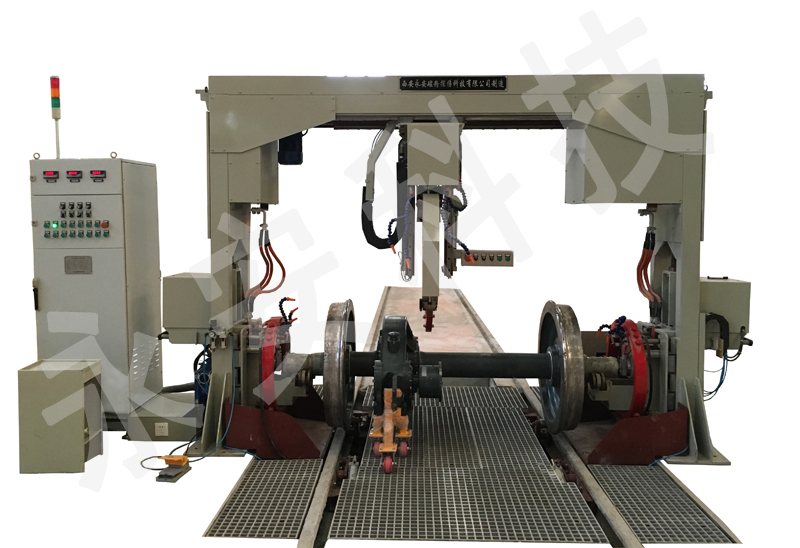

| JZD-B2型动车、地铁车辆轮对磁粉探伤机 适用范围 适用于动车、地铁车辆轮对大、中修时磁粉探伤 特点及技术指标 1. 龙门式主机结构,跨在轮对股道上,适合轮对通过式探伤的需要 2. 纵向磁化采用自主知识产权的镀银接点和双螺旋锁紧结构开合线圈,保证磁化线圈接点不发热不打火,线圈通电可靠,磁化效果稳定,线圈寿命长 3. 采用复合磁化,满足车轴轴身、牵引从动齿轮及车轮探伤需要 4. 对轴身进行磁化的开合线圈采用了可升降、移动机构,便于轴身纵向磁化 5. 轮对的旋转驱动具有变频调速功能,便于操作人员观察磁痕时方便地调节转速 6. 采用了先进的可控硅调流系统,磁化电流连续可调 7. 探伤过程采用进口PLC可编程控制器控制,操作简便可靠 8. 采用先进的电力补偿及控制技术,降低电源功率消耗 9. 磁化方式:周向磁化+纵向磁化+复合磁场 10. 最大输入功率:60Kw 11. 周向磁化峰值电流:0-4800A连续可调 12. 纵向磁化峰值电流:0-2800A连续可调 13. 检测表面磁场强度:≮2400A/m 14. 检测车轴长度:2040mm~2300mm 15. 检测齿轮回转直径:400-640mm 16. 检测车轮直径:700-1000 17. 退磁方式:原位衰减法 18. 检测灵敏度:清晰显示A1型标准试片15/50的人工缺陷 19. 剩磁:不大于0.3mT 20. 主机外形尺寸:3.9×1.05×2.4m 21. 主机总重:3000kg

JZD-B2 Magnetic Particle Flaw Detector for CRH & Metro wheel pair Applicable scope It is suitable for the surface magnetic particle testing of CRH & metro wheel pair, including bake disc,driven gear. Features and Technical parameters 1. The gantry structure of mainframe is suitable for the wheel pair detected through it, especially for matching the examining and repairing lines of wheel pair. 2. Longitudinal magnetization coil with independent intellectual property rights of the double helix locking opening and closing coil, guarantee the magnet coil contact not fever , magnetizing effect is stable, the coil have long service life 3. Compound magnetization and movable fan shape auxiliary magnetic device, meet axis,traction driven gear and the wheel testing needs 4. To the opening and closing magnetization coil of axis body, adopted a collapsible mechanism, protect rolling bearing from the magnetization 5. To the rotation of the wheel drive with frequency control , easy operater to adjust speed, observing magnetic mark 6. Magnetizing current controlled by SCR module of voltage regulation,It can be adjusted at any time 7. Inspection process adopts imported PLC programmable controller control, easy operation and reliable 8. Adopting advanced electric power compensation and controlling technology, reducing the power consumption 9. Magnetization mode: resultant magnetic field+rotating magnetic field 10. Input power: 60kW 11. The peak value current of circular magnetization:0-4800A continuously adjustable 12. The peak value current of Longitudinal magnetization:0-2800A continuously adjustable 13. Magnetic field intensity on detection surface: ≥ 2400 a/m 14. lenth of tested axis:2040-2300mm 15. diameter of tested gear:400-640mm 16. diameter of tested weel:700-1000mm 17. Demagnetization method: in situ decay 18. Detecting sensitivity: Clearly displays the artificial defect of A1 standard test piece 15/50(7/50) 19. Residual Field: ≤0.3mT 20. Mainframe exterior size: 3.9m×1.05m×2.4m 21. Mainframe weight: 3000kg

|