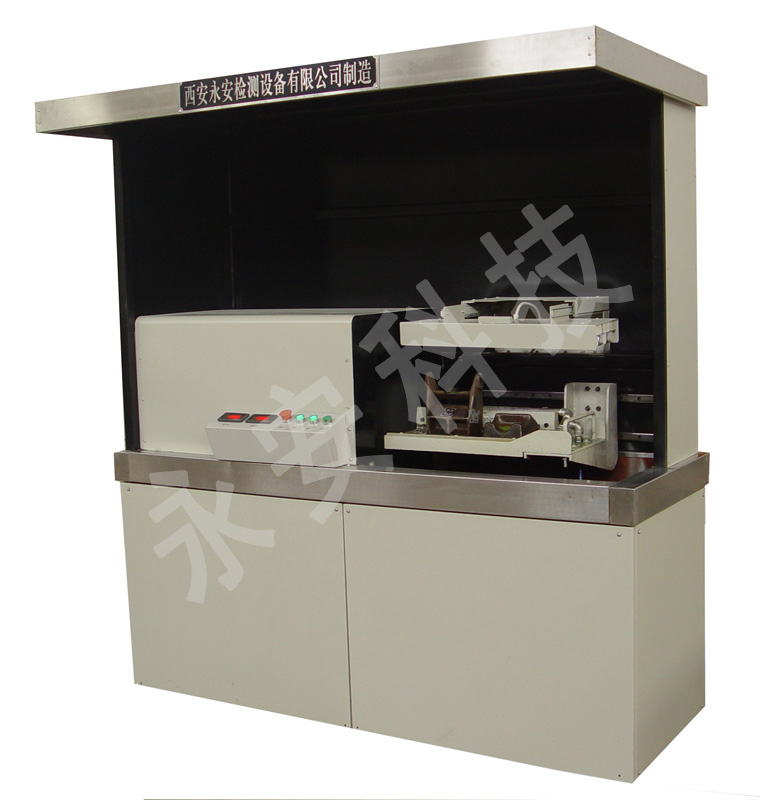

| XWD-A型旋转磁场小件探伤机 适用范围: 适用于各种小型铸锻件的磁粉探伤检测,如机车车辆车钩缓冲器内各种模锻件,货车侧架支承座,车钩钩舌销、钩尾销等的磁粉探伤 特点及技术指标 1. 采用自主知识产权的旋转磁场磁化技术对探伤零件非接触磁化,适应能力强,检测可靠 2. 隧洞式旋转磁场磁化装置配合可移动探伤工件托盘,适合小零部件探伤的需要,可实现一次磁化探伤多个工件 3. 探伤过程采用PLC控制,操作简便可靠 4. 磁化电流不等值衰减,剩磁小 5. 床式一体化设计,无须特殊基础,安装维修简便 6. 磁化方式:旋转磁场+周向磁场 7. 最大输入电流:60A 8. 旋转磁化磁动势:8000AT 9. 磁化装置空载中心磁场强度:≥2400 A/m 10. 检测灵敏度:清晰显示A1型标准试片15/50的人工缺陷 11. 磁化腔最小宽度:300mm 12. 托盘最大承载:15kg 13. 剩磁:不大于0.3mT 14. 主机外形尺寸(长×宽×高):2.4×1.0×2m(不含暗室) 15. 主机总重:680kg

XWD-A Rotary Magnetic Field Small Pieces Flaw Detector Applicable scope Applicable to all kinds of forging parts in the coupler bumper, bearings truck side frame, the tongue of coupler, the pin of coupler end and other small castings and forgings of magnetic particle testing. Features and Technical parameters 1. Adopt to the independent intellectual property rights of rotating magnetic field non-contact magnetization, magnetic field distribution more uniform, use and reliable 2. Tunnel rotary magnetic field magnetization and the using of the detecting tray can achieve more than one work-piece magnetic detecting; 3. Testing process adopting PLC programmable controller, so it is easy and reliable to operate; 4. magnetization current is not equivalent attenuation, remanence is small. 5. Bed type integration design, without special foundation, easy installation and maintenance 6. Magnetization mode: Rotating Magnetic field 7. The maximum of the input current: 60A 8. Rotating magnetization MMF: 8000AT 9. The center magnetic field strength of the magnetized device(no-load): ≥2400A/m 10. Detecting sensitivity: Clearly displays the artificial faults of A1 standard test piece 15/50; 11. The magnetization minimum of cavity width: 300mm 12. The maximum load of the tray: 15kg 13. Residual magnetic field: ≤0.3mT 14. Mainframe Contour Size(L×W×H): 2.4×1.0×2.0 m 15. Mainframe Gross Weight: 680 kg

|