|

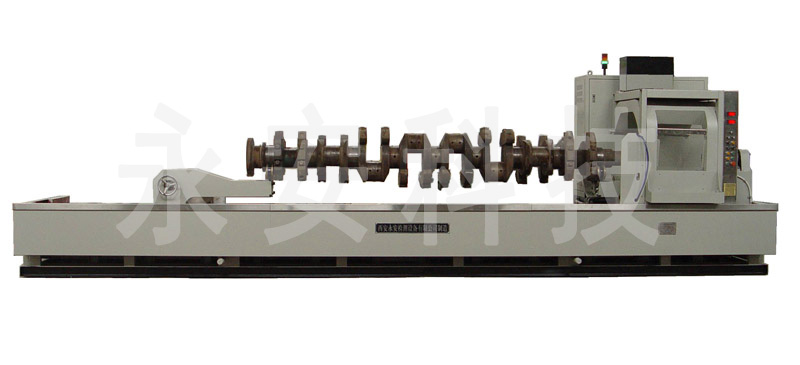

SQT-ⅠB型旋转磁场多功能曲轴探伤机 适应范围: 适用于铁路机车、舰船、电力等行业大功率中高速柴油机曲轴及其他零部件的磁粉探伤检测 特点及技术指标 1. 采用自主知识产权的旋转磁场磁化技术对曲轴等探伤零件进行非接触磁化,适应能力强,检测可靠2. 采用固定的及可移动的两个悬臂支撑曲轴,可兼容多种规格的曲轴的探伤作业 3. 磁化电流由可控硅调压模块控制,电流大小可根据检测的需要随时调整 4. 曲轴的转动采用了变频器控制,曲轴回转速度可调,便于观察磁痕 5. 探伤过程采用PLC控制,一键完成探伤全过程,操作简便可靠 6. 床式一体化设计,无须特殊基础,安装维修简便 7. 磁化方式:旋转磁场8. 输出功率:65kW 9. 磁悬液:油磁悬液或水磁悬液10.磁化峰值电流:0-2800A连续可调13.可检测曲轴最大长度:5000mm(可特殊订做)14.可检测曲轴最大重量:4000kg15.检测灵敏度:探伤部位清晰显示A1型标准试片 15/50的人工缺陷16.退磁方式:旋转磁场移位法和旋转磁场原位衰减法17.退磁效果:≤0.3mT18.主机外形尺寸:7.2×1.7×2.2m19.主机总重量:4600kg

SQT-IB Magnetic Particle Flaw Detector for crankshaft Applicable scope For the magnetic particle testing of crankshaft, in the high power middle and high speed diesel engine Used in railway locomotives, ships, electric power industries Features and Technical parameters 1. Adopt to the independent intellectual property rights of rotating magnetic field non-contact magnetization, magnetic field distribution more uniform, use and reliable2. Adopt the fixed and movable cantilever to support crankshaft, compatible with a variety of specifications of the crankshaft inspection work3. Magnetizing current controlled by SCR module of voltage regulation, current can be adjusted at any time according to the need of the inspection4. Adopted the variable frequency drive to control crankshaft rotation, speed can be set freely and realize dynamic commutation, easy to observe the magnetic mark5. Inspection process adopts PLC programmable controller control, easy operation and reliable 6. Bed struct integration design, without special foundation, easy installation and maintenance 7. Magnetization mode: rotating magnetic field 8. Input power: 65kW 9. Carrier fluid: oil or water 10. The peak value current of rotating magnetization:0-2800A continuously adjustable 11. Magnetization coil inner cavity section size: 850×850mm 12. Crankshaft maximum turning diameter can be detected: φ760mm 13. Crankshaft maximum lenth can be detected: 5000mm(Can be tailor-made) 14. Crankshaft maximum weight: 4000kg 15. Detecting sensitivity: Clearly displays the artificial defect of A1 standard test piece 15/50 16. Demagnetization method: in situ decay and displacement method 17. Residual Field: ≤0.3mT 18. Mainframe exterior size: 7.2m×1.7m×2.2m 19. Mainframe weight: 4600kg

|